What is a Micro Variable Frequency Drive (Micro VFD)?

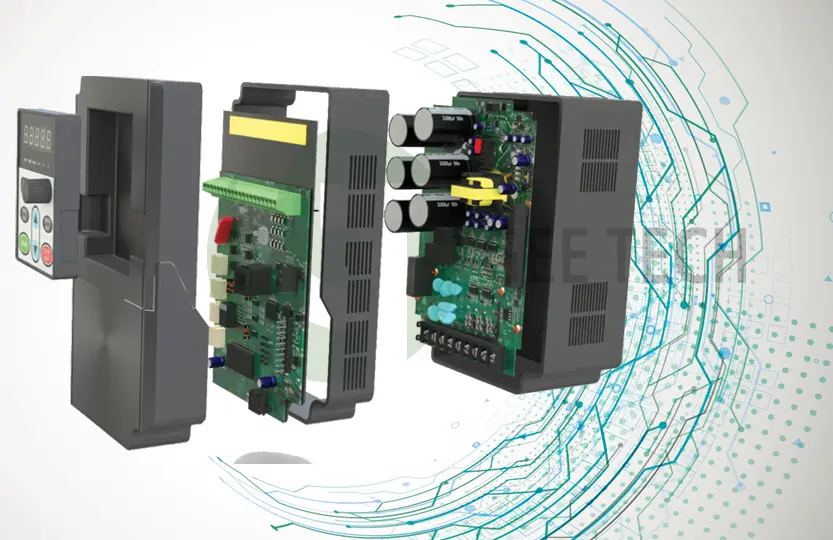

A micro variable frequency drive (micro VFD) is a compact motor controller designed for small-scale automation and low-power electric motor applications. Unlike traditional large VFDs, micro VFDs offer all essential functionalities in a smaller, cost-effective form, making them ideal for precise motor control in space-constrained environments.

Key Applications of Micro VFDs:

- Small pumps and fans

- Conveyor belts

- HVAC systems

- Laboratory and research equipment

- Home and commercial automation

- Compact machinery

Why Micro VFDs Matter in Modern Automation

As industries move toward smarter and more energy-efficient automation systems, micro VFDs have become a vital component. Here’s why:

1. Energy Efficiency & Cost Savings

Micro VFDs regulate motor speed according to the actual load demand, significantly reducing energy usage. This dynamic operation minimizes electricity bills, especially in industries like HVAC, food processing, and packaging.

SEO Keywords: energy-saving motor controller, efficient automation drives, compact VFD for motors

2. Precision Motor Control

Micro VFDs enable exact control over motor speed and torque, improving performance consistency in applications like miniature conveyor systems, mixers, or dosing pumps.

SEO Keywords: precision motor control, speed control VFD, small motor automation

3. Soft Start and Soft Stop

These drives gradually increase motor speed during startup and decrease it during shutdown, minimizing mechanical shock and extending equipment life.

Benefits:

- Reduced wear and tear

- Prevention of current surges

- Smooth operational flow

4. Extended Equipment Life

By limiting inrush current and reducing mechanical stress, micro VFDs extend the operational lifespan of motors and connected components.

5. Reduced Noise Levels

Lower motor speeds mean less noise, which is crucial for residential HVAC systems, medical devices, and office equipment.

6. Space-Saving Design

Micro VFDs are ideal for control panels, integrated systems, or mobile machinery due to their compact footprint and lightweight construction.

7. Dynamic Braking Capabilities

In applications requiring sudden stops, some micro VFDs are equipped with dynamic braking, ensuring controlled deceleration for enhanced safety and performance.

8. Remote Monitoring & IoT Compatibility

Modern micro VFDs support communication protocols like Modbus, Ethernet/IP, and Bluetooth, enabling remote monitoring, diagnostics, and control via HMI or mobile apps.

SEO Keywords: IoT-based motor control, remote motor monitoring, smart automation VFD

9. Built-in Protection Features

Micro VFDs come with integrated safety mechanisms such as:

- Overload protection

- Overheat shutdown

- Short circuit and fault diagnostics

- Voltage fluctuation handling

These ensure long-term operational reliability and reduce downtime.

Advantages of Using Micro VFDs in Automation

| Feature | Benefit |

|---|---|

| Compact Size | Saves installation space |

| Cost-Effective | Ideal for budget-friendly automation projects |

| Scalable | Suitable for multi-motor, small load systems |

| Plug-and-Play | Easy to install and configure |

| Sustainable | Supports green energy goals through energy savings |

Micro VFDs in the Automation Industry: A Growing Trend

The shift toward Industry 4.0 and smart manufacturing has accelerated the adoption of micro VFDs. With industries striving for modular, flexible, and energy-efficient automation, micro VFDs are paving the way for decentralized control systems and optimized power consumption.

Industries Benefiting from Micro VFDs:

- Automotive component manufacturing

- Food and beverage processing

- Pharmaceutical and chemical industries

- Water treatment and irrigation systems

- Smart home and building automation